2019-07-02

2019-07-02Elevator speed limiter - ten kinds of faults that may be cau

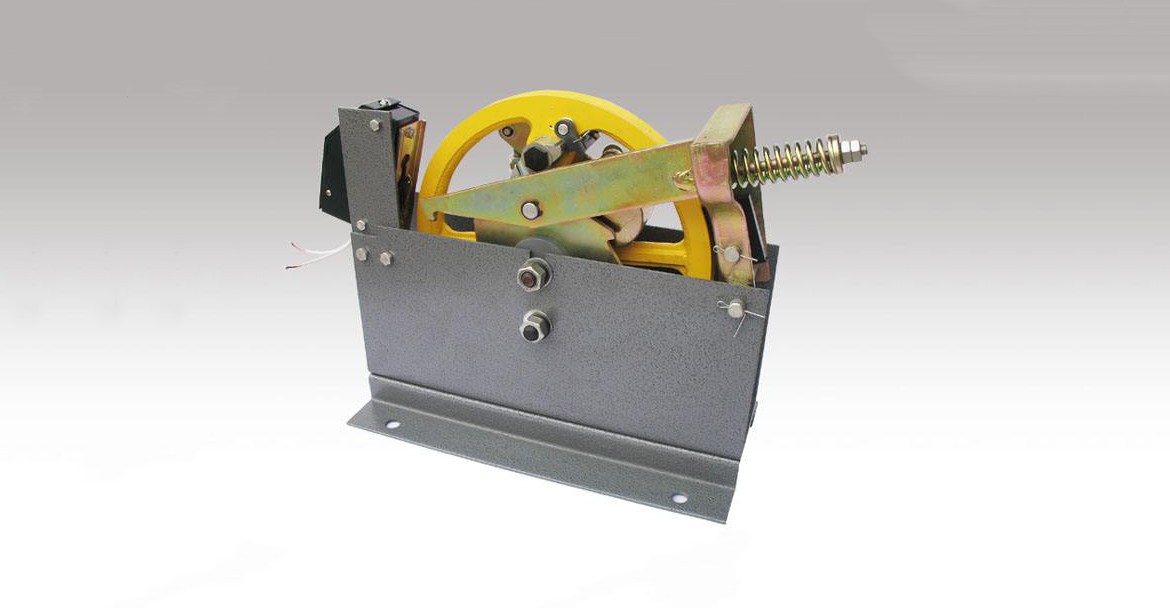

Elevator speed limiter - safety clamp linkage test is an important test that must be done for elevator acceptance inspection and periodic inspection. It requires the car to evenly arrange the corresponding load. In the machine room, the artificial speed limiter is operated to control the elevator to level or repair the speed. Run down to make the speed limiter electrical switch. Then short the speed limiter and the safety clamp electrical switch, so that the speed limiter wire rope brakes and then pulls the safety clamp device, clamps the guide rail, and stops the car. After the test is completed, the various mechanisms and electrical switches should be restored to normal, and the rails should be inspected for damage, etc., and repaired to a normal state if necessary. The test process is not complicated, but the resulting elevator failure is a wide variety.

1 speed limiter electrical switch reset is not in place, causing malfunction

Elevator speed limiter - After the safety clamp linkage test, although the mechanical part of the speed limiter's electrical switch is not reset, the contact of the speed limiter's electrical switch has been turned on. If the elevator is put into normal operation at this time, the speed limit is set. The vibration caused by the rotation of the wheel may cause the switch to malfunction, causing the elevator to stop.

2 speed limiter electrical switch bump deformation or damage

In order to verify that the electrical switch of the speed limiter can act before the action of its mechanical device, it is necessary to maintain the initial position of the electrical switch before the artificial action speed limiter, thereby touching the switch by the mechanical device of the speed limiter, but also due to the above limitation The reason why the mechanical part of the speed switch is not reset, or the reason for the speed limiter manufacturing and assembly accuracy, the mechanical device of the speed limiter is very likely to deform or even break the collision arm of the switch. The occurrence of such a fault, although the normal operation of the elevator can be restored after the electrical switch is reset, the deformation of the switch arm will cause the actual speed of the electrical switch of the speed limiter to increase or even fail, thereby causing a serious elevator overspeed accident.

3 overload or overcurrent protection

After the safety gear moves and the car is reliably stopped, the speed limiter and the safety clamp electric linkage switch are short-circuited. Under normal conditions, the friction between the traction wire rope and the traction sheave is less than the output torque of the traction machine. The continued rotation of the traction sheave will cause the traction wire to slip. However, if the friction between the traction wire rope and the traction sheave is greater than the output torque of the traction machine, the following two situations may occur: one case is that the stator power supply current of the electric motor has exceeded its rated current, but has not yet reached The setting value of the flow protection relay, although the motor cannot rotate, it is easy to cause the motor to heat up and the overload protection action. In another case, the stator power supply current of the motor has reached the setting value of the overcurrent relay, and the overcurrent protection will immediately act to stop the motor. Some elevators' microcomputer systems will save the fault record at the same time. Even if the power is turned off, the microcomputer will not be able to operate normally. After the fault is removed, the fault record must be cleared to restore the elevator to normal.

4 safety gear can not be reset

Speed limiter - After the safety gear linkage test, the safety gear can not be reset is also a common fault. If the performance is light, the car guide rail will have a "beep" friction sound, and the car will not be able to move up and down. There are three main reasons why the safety gear cannot be reset. In one case, when the safety gear moves, the wedge should be wedged between the guide rail and the safety nozzle. If the machining error is too large or the installation is poor, the wedge clamping work surface and The guide rails are not parallel, and the sharp edges of the end faces of the wedges may break into the guide rails, so that the safety gears cannot be reset. In another case, the safety clamp lever springs have insufficient reset force to lift the tie rods and wedges; the third case is that the tie rods are bent. And it is stuck with other mechanical devices and cannot be reset.

5 safety clamp linkage switch reset is not in place or can not be reset

Similar to the above-mentioned speed limiter electric switch, after the test, the mechanical part of the safety clamp linkage switch is not reset, and the vibration after the elevator is put into operation may also cause the switch to malfunction, causing the emergency stop of the elevator. If the safety gear and its tie rod mechanism are not completely reset after the speed limiter-safety gear linkage test, the safety clamp linkage switch will also be difficult to reset, so that the elevator cannot resume operation.

6 rail scratches cause malfunction of safety tongs, etc.

Speed limiter - After the safety clamp linkage test, the car guide rail should be inspected on the top of the car to be scratched by the wedge, and according to the weight of the trace, use the hand grinding wheel or trowel, oil stone, sand cloth, etc. Smooth and polished. If the car guide rail damage is large after the test, and the elevator is put into normal operation without grinding, the friction sound of “嘶嘶” may appear at the car guide shoe, or the displacement of the car top cup felt may be caused. Or damaged. In the meantime, the safety tongs may be caused by the burrs of the guide rails, causing the car to have an emergency stoppage, which may cause more damage.

The tensioning of the 7 tensioner and its counterweight causes the speed limit rope to relax.

This is a very difficult phenomenon that is easily overlooked but extremely dangerous. After the speed limiter is actuated, because the rope clamp tightens the speed limit rope tightly, if the speed limiter rope clamp is not manually reset, the elevator is operated to check the speed up, and the speed limiter rope can also be realized. Reset of the device and safety gear. However, if the force of resetting the rope gripper is greater than the force of the speed limit rope lifting the speed limiter tensioner and its counterweight, the elevator car's ascending will lift the speed limiter tensioner and its counterweight through the speed limiting rope. . Moreover, this lifting will go far beyond the effective working range of the tensioning wheel and its counterweight guide. Therefore, the possibility of jamming of the tensioning wheel counterweight and its guiding device is inevitably greatly increased. If the jamming occurs, but it is not discovered and eliminated in time, when the elevator is put into normal operation, the speed-limiting rope is still in a completely slack state due to the loss of tension, and the speed-limiting rope and the inner rail bracket of the shaft are easily prone to occur. Mutual interference of devices such as leveling sensors, or the speed-limiting ropes coming out of the speed-limiting wheel groove, or even being pulled off, the consequences are unimaginable.

8 tensioner electric switch malfunction

Also for the above reasons, the elevator car's ascent is lifted by the speed limit rope to the speed limiter tensioning wheel and its counterweight. Moreover, this increase may well exceed the effective working range of the tensioning wheel and its counterweight guide. However, the possibility of being completely stuck is not large. More often, after the tensioner and its counterweight are lifted, it is quickly lowered due to the reset of the speed limiter rope gripper. If the distance between the speed limiter disconnection switch and the collision of the iron is not large enough, the elasticity of the upper limit speed rope, the inertia of the tension wheel and its weight falling may cause the broken rope switch to malfunction, thereby stopping the elevator.

9 cars significantly tilted

After the safety gear is actuated, the car may show a significant tilt. The main reason is that the safety clamp wedges and the guide rails are inconsistent, causing the safety clamps on both sides of the elevator car to fail to operate at the same time, which causes the overall force of the car to be unbalanced, and the car tilt phenomenon occurs. In addition to adjusting the car diagonal tie rod and correcting the car, it is also necessary to adjust the gap between each safety wedge and the guide rail and the linkage device so that the movement gap of each mechanism is uniform.

10 safety mouth deformation or cracking

At the time of acceptance inspection, the test is subjected to a rated load or a rated load of 125%, and the impact caused by the test is large. Especially for the instantaneous safety gear, the kinetic energy and potential energy of the car will be instantaneously transformed into the extrusion deformation of the wedge and the guide rail and the extrusion deformation of the wedge and the safety nozzle. If the safety factor of the safety nozzle does not meet the relevant standards, It is very likely that plastic deformation or even cracking will occur after the test.

The above only lists the speed limiter - ten kinds of fault phenomena that are easy to occur in the safety clamp linkage test. In actual tests, more faults may be encountered. If the short-circuit number is wrong, the other electrical components are damaged when the safety circuit is short-circuited; the vibration of the test causes damage to the interior of the car or the decoration falls. Therefore, the elevator speed limiter-safety gear linkage test is a risky test. In actual work, it must be cautious and prudent, and strictly follow the operating procedures.