2019-07-03

2019-07-03How to quickly confirm elevator failure

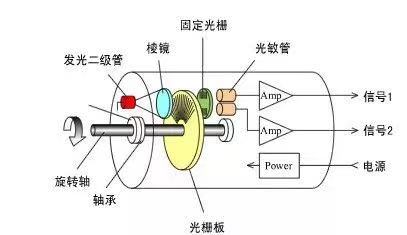

1、Confirmation of rotary encoder failure

Example 1: A GPS-‖ elevator, the leveling layer is inaccurate in the running stroke. There is a phenomenon of “Teng Yiteng” in the running stroke. In the maintenance, it took a lot of effort to go a lot of detours and finally found it because of the rotary coding: 9 several photoelectric The induction hole is blocked by dust and the fault is eliminated after cleaning.

Example 2: An P90-50 elevator has an abnormal phenomenon after the air car safety clamp-speed limiter linkage test. After the elevator layer is started, it crawls about 50mm and stops. Think about it. Since the elevator has operating conditions There are no obvious other anomalies, so it is definitely a problem with the rotary encoder. Finally, the reason is that the connection between the rotary encoder and the microcomputer has a virtual connection.

Example 3, a VVVF elevator often stops suddenly during operation. Then it automatically runs after leveling. After the gun is detected, the fault is not caused by poor brake circuit. It is also not caused by the instantaneous opening and closing of the safety circuit and the door lock circuit. But because of the serious wear of the rotary encoder, the elevator caused a sudden interruption of the signal during operation.

Example 4: 1 GPS-CR elevator maintenance operation Normally, the car oscillates strongly when the express train is running, and the elevator regularly shakes up and down, especially in multi-layer operation. This is especially true after checking the main circuit printed circuit board and drive unit of the elevator. Still did not find the real reason. After asking the owner, it was found that some people in the machine room to remove debris, the elevator began to appear above. After the inspection of the traction machine and the control cabinet, the PG was used to measure the speed feedback. The distortion of the grounding copper skin makes the motor shaft and the Pc bushing different in operation during the operation. After re-machining a piece of connecting copper piece, the fault phenomenon is eliminated after replacement.

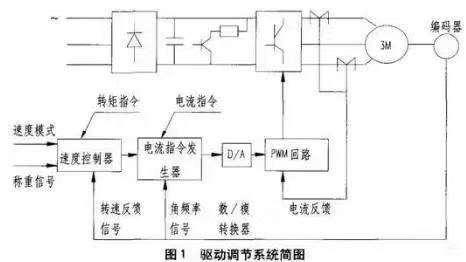

The fault caused by the rotary encoder is not a few checks in practice. It is quite troublesome. Sometimes it has been checked but it is still not reassuring. So I will introduce you to a simple method to confirm the rotation coding fault from the drive adjustment system. The figure can clearly see that the rotation of the microcomputer causes the microcomputer to be between the inverter and the motor. It constitutes a speed closed-loop control system. If the problem occurs in the transcoder, the feedback signal is not normal, which will affect the normal operation of the motor. If so, we simply disconnect the feedback of the rotary encoder into an open-loop control. If the motor can still be in the normal fast running state, then the fault of the elevator can be generated on the rotary encoder, otherwise it should be found in other aspects. This is the theory and method to confirm the fault of the rotary encoder.

Of course, for safety reasons, the elevator should not run to the upper and lower ends when the feedback operation is turned off.

2. Quick confirmation of the position of the door lock fault

The failure of the door interlock accounts for a relatively high proportion of elevator failures. For the door interlock failure, it is easy to confirm in the equipment room control cabinet by checking the display or comparing the fault codes. If the elevator has fewer floors, we can find it one by one and eliminate it one by one. However, if you encounter high-rise buildings, such as high-rise buildings of forty or fifty floors, how to quickly and accurately find the landing of the door interlock failure? When the door interlock is faulty and the elevator cannot be operated, the car door switch terminal and the hall door switch terminal should be found on the terminal block of the equipment room control cabinet. In the case where the car door and the hall door are all closed, the car door switch and the hall door switch are respectively measured to be turned on. If the measurement result is that the car door switch is turned on and the hall door switch is turned off, the following segmentation method can be used to continue the judgment.

Shorten the 01 and 11 lines on the door lock circuit first so that the elevator can operate up and down. The maintenance personnel enter the car top and find lines 01 and 10 on the car top junction box. Assume that the elevator is 40 floors and 40 stations, press the car top slow button to the middle floor station, such as the 20th floor station, open the car door and hall door of the 10th floor station, and the rest of the hall doors are closed. One wire is connected to the car top wire No. 01 line, the other end is connected to the multimeter one meter pen, and the other meter pen is connected to the contact point of the door interlock switch of the 20-story hall door. If one of the two contacts of the interlock switch is connected with a multimeter, it means that the 21st to 40th station door interlock switches are all turned on; if the multimeter is not turned on, the 21st to 40th station door interlock switches are indicated. There is an open road. The same method can be used to judge the 1~1 9-station door interlock switch. As for the 20th floor station, the two contacts of the door interlock switch can be measured to be turned on and off after the door is closed. Then, take the 1/2-story station as the measurement point in the half-floor station that has judged the open circuit, so that it can quickly find the landing station with the door interlocking open circuit.

3, the door knife hits the door roller fault confirmation

The elevator has a sudden stop in operation, which may be caused by the momentary opening and closing of the door lock circuit (man-made splitting), or it may be caused by the speed limiter tensioning device touching the broken rope switch in an instant, and of course It is caused by the doorknife touching the door roller during the running. If you open a professional elevator repair book, you will also see that there are at least some reasons for the day to cause a sudden stop. So, how to confirm the failure of the doorknob to touch the door roller?

For elevators controlled by PLC, the program shown in Figure 2 can be inserted between OUT (M21) and OUT (M111) of the program, where M21 is the running relay and X14 is the door lock relay contact. After the fault occurs, check the K value of the counter C224 in the PLC and compare it with the K value of the last check. If it is found that it has been increased once, it is sure that there is a problem that the door has a doorknob.

Maintenance personnel often encounter a variety of phenomena in their work. If you carefully check and analyze, and be good at summing up, it will provide a lot of shortcuts for future work.

4, the reason why the elevator can not close the door

1) The elevator enters the protection state

2) Light curtain or safety touch panel failure

3) The door open button or the outer call button is stuck

4) Mechanical stuck

5) The motherboard cannot output the closing signal

6) overload

7) The switch door is not in place.

8) Door area switch failure

5, the reason why the elevator can not open the door due to normal parking

1) The elevator enters the protection state

2) Door area switch failure

3) Car door mechanical jam

4) The hall door hook lock is not adjusted.

5) The main board does not send a door open signal

6) Door system failure

7) Door encoder failure

Example 1: An elevator, the leveling inaccuracy has the appearance of "Teng Yi Teng" in the running stroke. It took a lot of effort to repair. Many detours were found at the end of the road. It was found that it was due to rotary coding: several photoelectric induction holes were dusty. Blocking and eliminating the problem after cleaning.

Example 2: An elevator presents an abnormal appearance after the air car safety clamp-speed limiter linkage experiment. After the elevator layer is started, it will be about 50mm, and it will stop. It is thought to go. The elevator has operating conditions and no Significant other anomalous appearances are certainly a question of the rotary encoder (electronic handwheel). The final reason is that the connection between the rotary encoder and the microcomputer has a virtual representation.

Example 3: A VVVF elevator often stops in operation during operation. Then it can operate normally after being leveled. After the gun is detected, the fault is not caused by the bad brake circuit. It is also not caused by the opening and closing of the safety circuit and the door lock circuit. However, due to the severe wear of the rotary encoder, the appearance of the signal in the elevator during operation is abruptly stopped.

Example 4: 1 elevator operation and normal operation When the express train is running, the car vibrates violently, and the elevator has a regular up and down vibration, especially in the multi-layer operation. This appearance is particularly noticeable. After viewing the elevator main circuit print plate and the drive unit, it is still not Find the real reason. After inquiring the owner, it is known that some people in the machine room to remove debris, the elevator starts to show the above appearance. After viewing the traction machine and the peripheral side of the control cabinet, the PG grounding for the speed response is found at the rear of the motor. The distortion of the copper skin makes the motor shaft and the bush of the Pc different in the operation of the elevator. After that, a piece of copper piece is processed from the beginning, and the appearance of the defect is eliminated after replacement.

The elevator problem caused by the rotary encoder (encoder selection) is not a small amount in practice, and it is also very troublesome to look at. Sometimes it has been checked but it is still unsettled. Therefore, we will introduce a simple trick to us. The recognition of the problem of rotary coding is precisely because of the rotary coding, which makes the speed-closed-loop control system between the microcomputer and the inverter.

If the transcoder is in doubt, the reaction signal is abnormal, which will affect the normal operation of the motor. Suppose we simply disconnect the reaction of the rotary encoder at this moment - it becomes an open loop control, and the motor can still be in normal speed. Operational conditions, then you can conclude that the elevator's fault does occur on the rotary encoder, otherwise it should be found in other aspects. This is a theory that recognizes the problem of rotary encoders.